In Crawlspace ventilation again, I mentioned the problem that I was having with the fans whining if the power supply could not provide enough power:

With the 8Ω series resistance, the 4-fan load had a hard time getting started, and whined a bit before starting. Once one of the fans got up to speed and reduced its current draw, the others quickly came up to speed also. The regulated voltage was only 4.9V, and fluctuated a bit, rather than the constant 5.02V with smaller loads or less series resistance between the 9V power supply and the regulator.

With the 10Ω series resistance, the 4-fan load could not start at all, but just whined. The output of the regulator was only 2.2V while the fans were stalled. If a 4th fan was added while 3 fans were already running, the fans ran, but with a 4.11V regulator output. (The three fans had already reduced the regulator voltage to 4.99V).

…

I may have a little trouble with the fans each morning as the power comes up gradually—they may have trouble starting if the panel is not yet putting out enough power. If that turns out to be a problem, I may need to add some circuitry to detect low voltage on the regulator and turn off one or more fans.

The fans I’m using have brushless motors, which means that they include electronics to set the speed of the fan. Based on the electrical noise I see on the power line, they appear to have a constant frequency independent of whether the fan is spinning or not. This simple design for the electronics is cheap, but not as good as a design that detects the speed of the motor and optimizes the phase and frequency of the rotating magnetic field to maximize torque or efficiency. The whining at low power when the fan is not turning seems to be at the frequency at which the fan is expected to spin with a 5V supply, but I’ve not used a microphone to check.

I tried two different approaches to handling the low-voltage problem:a power-on-reset chip and a simpler FET circuit of my own design.

The first design was to use a power-on-reset chip and an nFET to turn off the motors when the voltage was too low. This was inspired by the standard Miller engine used in solar motor toys to harvest energy from low-current solar cells, store it in a capacitor, and discharge the capacitor through the motor when there was enough charge. This did not work well, as the voltage from the regulator quickly got up to 5V when there was no load, but dropped almost immediately when the fan was turned on, causing the reset chip to turn the fan off again. The chip I was using, MCP100-450DI/TO has only 50mV of hysteresis, so it would turn off again almost as soon as it turned on, and then wait for 0.3 s before turning on again. The 50mV hysteresis meant that I’d need a large storage capacitor to get the fans past their initial high-current startup—I estimated around 15F, which would be an expensive supercapacitor. Without a huge capacitor, this circuit resulted in pulsed whining when the power supply was not capable of delivering the full 5V, which was even more annoying than the steady whine.

The second design I tried was just using the exponential turn-on of an nFET to provide full current when the voltage was high enough, but limit the current to very low levels when the voltage was insufficient:

The large capacitor on the gate keeps the transistor on for a while even after the voltage starts dropping.

One essential part of the circuit was the large electrolytic capacitor on the gate voltage. Without it, the voltage on the gate would rise to a point where the motors were struggling to start and stay there (when the power supply was provided with too low an input voltage). With the capacitor in place, the fans would continue to get current even as the voltage dropped a bit, giving them enough time to spin up and reduce their current load. Eventually the gate voltage would drop enough to start pinching off the current and the fans would hesitate and need to be spun up again. The result was that the fans would start even with a large series resistance between the 9.26V power supply and the input to the regulator (16Ω and sometimes even 32Ω), but not run smoothly unless there was enough power being delivered to the power supply for their continued running.

A smaller capacitor (220µF) worked also, but the fluctuation in speed happened more rapidly. Much smaller (33µF) did not filter the power-supply fluctuation enough to hold the fans on long enough to start up cleanly.

Adding capacitance across the 5V terminals decreased the electrical noise, but did not seem to change the behavior of the circuit.

The flyback diode (the BAW62) is probably not necessary with these fans, since the brushless-motor controller built into the fans undoubtedly has its own flyback diodes. I saw no evidence of inductive spikes when turning off the nFET.

So far I’ve only breadboarded the nFET control circuit, but I’ll probably solder it up later this week, when I get some time.

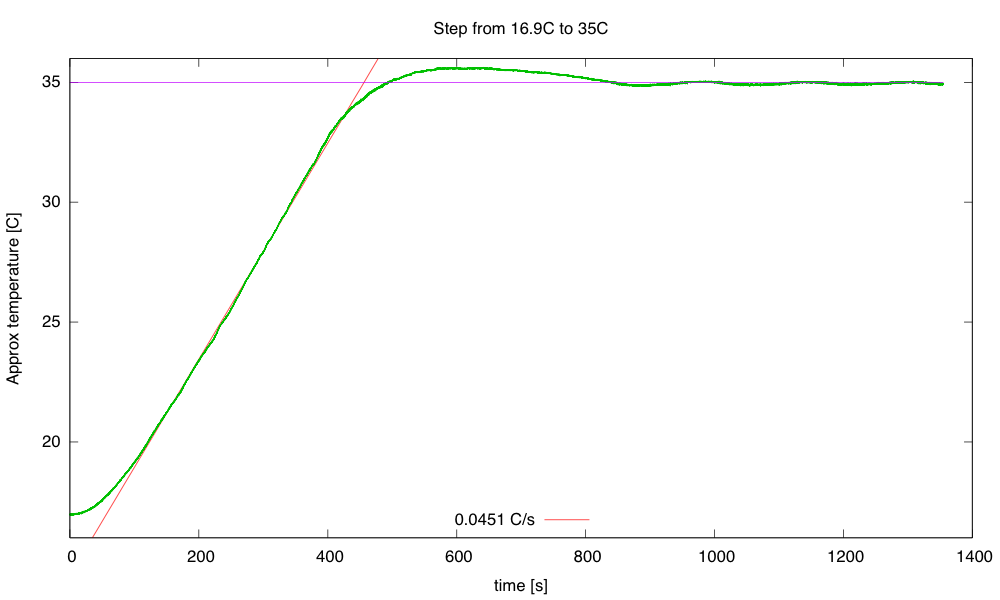

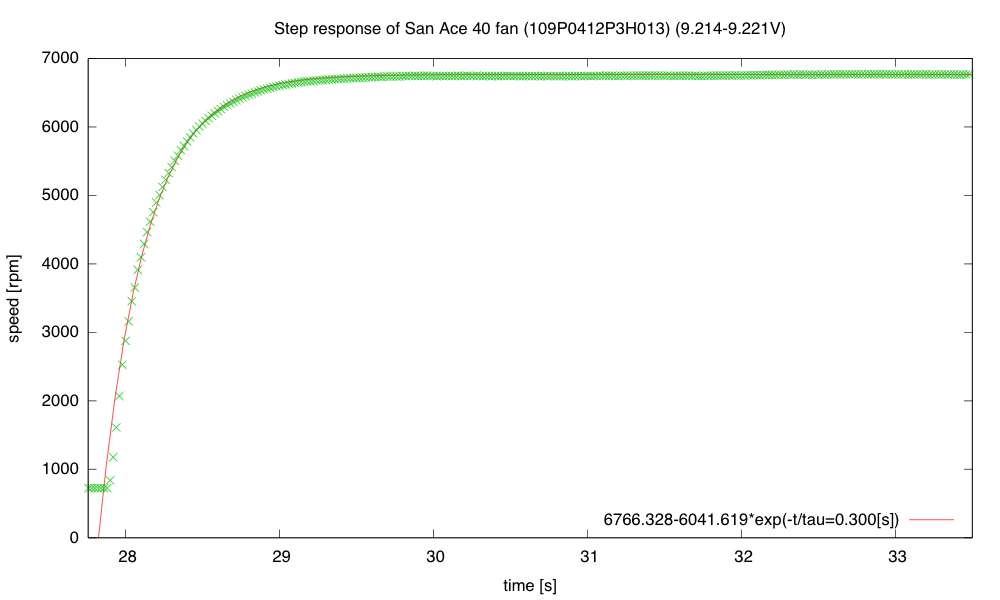

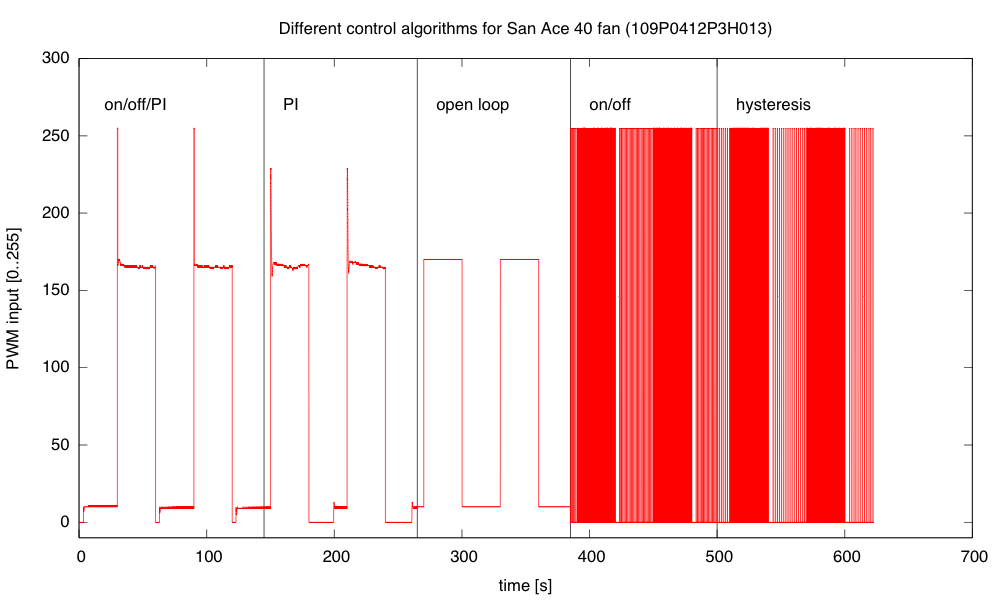

![The mixed algorithm does a very good job of control, with little overshoot. The simple PI algorithm has substantial overshoot, particularly when the control loop wants a PWM value outside the range [0,255]. Open loop has significant offset and wanders a bit. On/off control oscillates at about 10hz, and adding hysteresis makes the oscillation larger but slower (about 5Hz).](https://gasstationwithoutpumps.files.wordpress.com/2014/09/fan_multiple.png?w=1000&h=600)