I continue to be pleased with this Spring’s class. It is taking up far too much of my time, but the students are doing well. Today they got their resistors (and ceramic capacitors), so they could select whatever resistor value they needed for the optimization problem. I told them by e-mail last night to optimize for 12°C, which I estimated would require about a 12kΩ resistor. I change the temperature point each year, so that students can’t just look up an answer—not that it would do them much good if they could, as the design report needs to contain the derivation of the result. If they can copy the math correctly, then they can do it (especially since we did the derivation in class yesterday).

I put some reminders/instructions on the board at the beginning of lab, something like the following:

- Optimize for max sensitivity @ 12°C

- Measure your resistor

- Measure Vin

- Measure Vout at many temperatures

- Plot Vout vs temp both from model (as curve) and as data points, to check calibration.

- Plot temp vs time for 10 minutes of water warming up from low temperature (using PteroDAQ)

Everyone seemed to be getting good data in the lab. What students seemed to need the most help with was the concept of putting the predicted behavior of the circuit on the same graph with the measured behavior. They had a formula for the voltage as a function of temperature with 4 parameters: B and R∞ from fitting Tuesday’s data, R that they chose and measured, and Vin that they measured though it was nominally 3.3V. But it was hard going trying to convince them to plot that curve on the same graph as the scatter diagram of today’s measurements. It may be that they have never been asked to plot a predicted curve and measurements on the same plot before—as if they’ve never actually checked that a model is correct. I would have thought that physics classes would have done that sort of predictive modeling, but apparently not, as the concept seemed completely foreign to many of the students.

Those who did finally get the calibration plot done generally had very good agreement between their measurements and the predicted model. I’m hoping the rest will get the plots done tonight. There was at least one group that was seeing about a 0.5°C discrepancy, which could be due to different calibration of the thermometers used on Tuesday and today, or could be due to their using a wrong value for the °C to °K conversion.

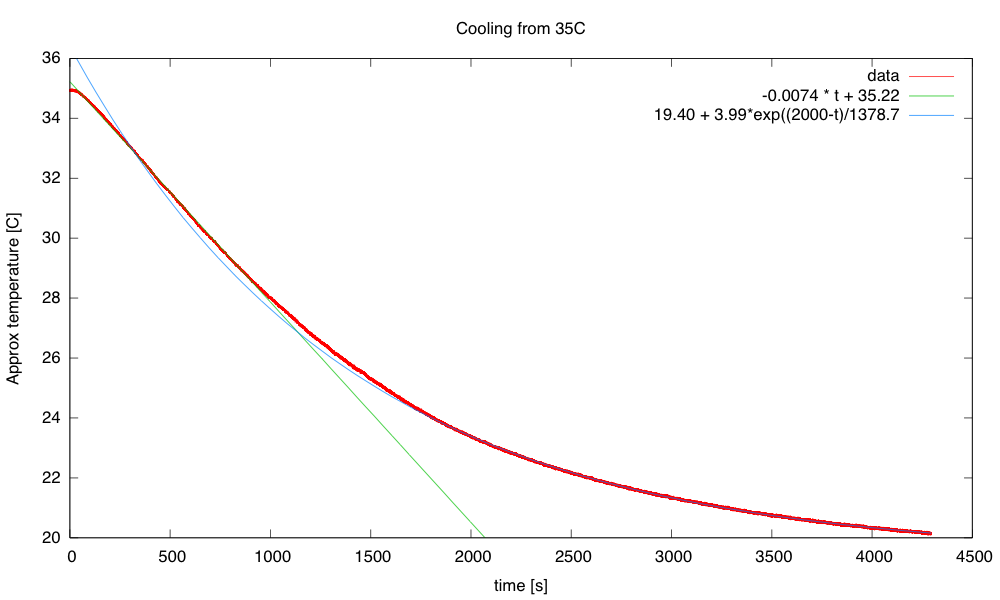

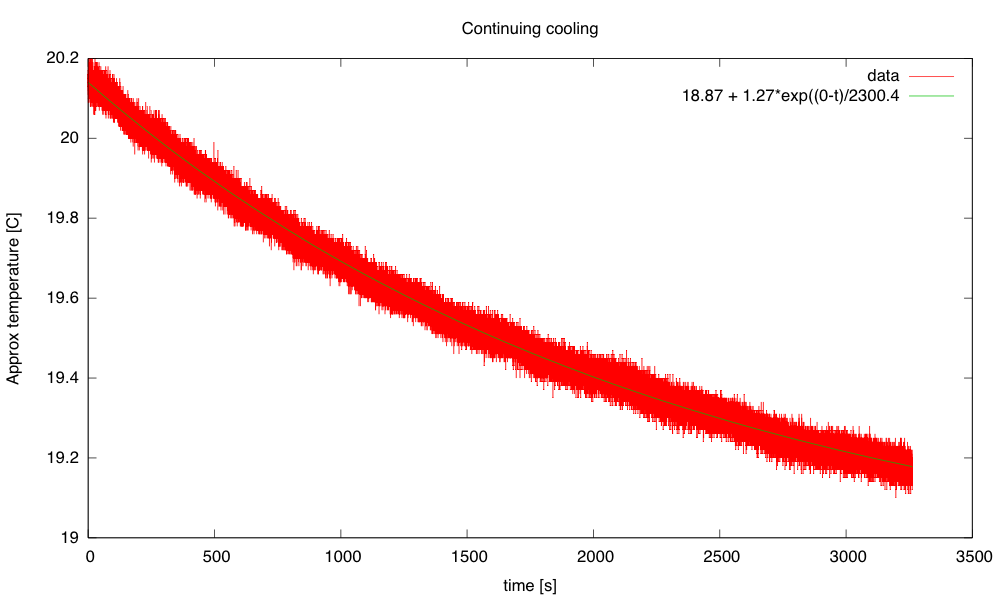

The students also recorded a time course of a water bath warming up from about 3°C. I think that next year I might do a higher optimum temperature and ask students to record a water bath cooling down—the temperature change is faster that way (due to evaporation). I’ve asked them to plot this as temperature vs. time, not voltage vs. time, and several students seemed well on their way to doing that correctly—this year’s class seems much more adept at picking up gnuplot techniques than the last two years’ classes. I don’t know whether that is because of a better ordering of the material this year, or some difference in the cohort. I like to think it is an improvement in the way I present things, but it is more likely to be a difference in the students.

One pair of students surprised me in a good way—they had done the optimization last night, then tried out the design at home, using the PteroDAQ to read voltage. Since they did not have the resistor kits yet, they had put the two 22kΩ resistors they did have in parallel to make an 11kΩ resistor. They were worried I might be upset with them for jumping the gun on the lab—quite the contrary, I’m delighted that they’re preparing before class, and that they realized that a lot of the lab work doesn’t really require the fancy equipment in the lab. I’ve pitched the class as being suitable for creating electronics hobbyists, and if some of them get into that early in the course, then the course is being highly successful!

I’ve even considered rewriting a number of the labs to be doable completely at home, but right now too many would require about a $250 investment in a USB oscilloscope, which makes an all-at-home approach a bit too expensive for me to recommend. It might be an interesting way to market the book though—as a complete electronics at home lab course for about $400. I think that there is a substantial market for such a kit/course, but it would be a fair amount of work to get the book into shape for use without a lab mentor to guide the students through the rough spots.

I’m looking forward to this week’s reports (that’s right, for once I’m looking forward to the grading, rather than dreading it), as I think that a lot of the class actually got all the concepts that this week’s lab was about.

Tomorrow I’ll be introducing complex impedance (particularly ) and RC filters as voltage dividers. I’ll be doing most of the lecture as a chalk talk, but I’ll bring my laptop to show them how to create (amplitude) Bode plots with gnuplot. We’ll be doing various things with model fitting, with variants on voltage dividers, and with complex impedance for the next 3 weeks, and then we’ll start on amplifiers.