My son and I have started on his summer project while he is home for winter break—to build a moderately bright, adjustable color theater light for WEST Performing Arts, the children’s theater troupe he has worked with for the past 11 years (including the two years before they split off from Pisces Moon).

The design is still very much in flux (we’re on our third processor choice already), and we haven’t done any parts ordering or physical prototyping yet, just thinking about circuits, parts, and layout. We are currently planning an RGBW light with DMX control, with 20W each of red, green, and blue LEDs, and 40W of warm white LEDs, all mounted in a PAR-38 can (using an old can from WEST, rather than buying a new can). The light will be a simple flood, which is easier to construct than a fresnel or spot light, because we don’t have to concentrate all the light into a small spot for manipulating with lenses. Currently WEST uses 75W or 100W incandescent bulbs in their PAR cans, so the LED light should be three or four times brighter. There are RGBW lights from China that are about the same brightness as we’re aiming for, but they are larger and more expensive—we’re aiming for a budget of about $100 a light for parts. (We’d not be able to sell them any cheaper than the commercial lights—this is just a hobby project to make one or two lights for the theater.)

The theater has a few 15W RGB lights with DMX control, the American DJ Mega Tripar Profile, but they are only 5W per channel (not really bright enough) and it is not clear what functionality the DMX controller for them has (we didn’t look at it or find out the model number). Because the set was a very cheap lighting set, it probably can’t handle the greater functionality we’re planned for the RGBW lights, so we’ll probably have to find or design a simple DMX controller that can be run from a Mac laptop. There are some open-source DMX controller projects on the web, but their user interfaces may be a bit too complicated for the kids (or non-techy staff) running the light booth for WEST. It is not clear whether we can design a simpler interface for a small number of lights that provides easy access to all the functionality of the lights. There is also the question whether a traditional control board with sliders or an all-virtual laptop-based controller is a better interface for beginning lighting techs.

We might even want to look at an iPad-based controller, like Luminair ($90), LightingPad (discontinued), and RunTheShow (free, but limited to controlling their particular hardware). LightingPad says that they have pulled the product until they can update for iOS8, which was released over a year ago—since iOS9 has come out before they updated to iOS8, it seems unlikely that they will ever be able to keep up with the churn in the iPads (a complaint I’ve heard from other iPad app developers—Apple makes it very difficult for older apps to keep running, requiring a full-time developer just to keep up with Apple breaking things on each release). Hmm, I seem to have talked myself out of developing an iPad app, but we probably should make sure our hardware can run with controllers like Luminair.

For laptops, there are open-source projects like Elios and WhiteCat. Elios is an open-source project in Java, but it hasn’t been updated for a couple of years, so may be a dead project. WhiteCat seems rather complicated, based on the screenshots at http://www.le-chat-noir-numerique.fr/index_eng.html, and most of the documentation is in French, which neither my son nor I reads.

Since we’re mainly interested in running on MacBooks, the OS-X-only code from LightKey may be usable. They have a free version with 24 channels that might be usable, though upgrading to more channels gets into an expensive subscription model.

The controls we are planning for the RGBW light were 16-bit PWM on each of the 4 channels, plus a strobe frequency (in units of 0.1Hz, with 0–5 and 250–255 having special meanings—probably always off and always on). Because the DMX512 protocol only has one byte per channel, the light would need 9 channels, and the free version of LightKey could only control 2 such lights.

The Tripar Profiles can be configured as anywhere from 1 to 7 channels:

- choice of 16 preset colors (“color macros”);

- 16 colors plus 1-byte dimmer;

- RGB;

- RGB plus master dimmer;

- RGB, dimmer, color macros;

- RGB, color macros, strobing, master dimmer;

- RGB, color macros, strobe or program speed, preset programs, master dimmer.

The preset programs are mainly for running the light as a standalone light show without a DMX controller, so we would not want to emulate that. The 4-channel RGB,dimmer function is intended as a workaround for the low resolution of 8-bit PWM control—you pick the color at full brightness, then multiply by the dimmer setting to get the overall effect. Since we are planning to use 16-bit PWM, we can get more precise color control even at dim light settings. If we mix our light with the Tripar Profiles, we would probably use the Tripar Profiles in 4-channel mode (unless we needed strobing, in which case we’d use 6-channel mode).

I mentioned above that we’d been through three different processor choices. At first we thought of using a Teensy board, because we’re familiar with ARM programming, the Teensy boards are easy to program, and they can be treated like a through-hole part for doing prototyping (by adding some header pins). But the boards are a bit large, and a bit expensive ($11.65 for a Teensy LC), so we next considered using an ATtiny2313A processor (again, the ATtiny is easily programmed and I have some experience with the ATtiny13, which I used for the PWM on my desk lamps). Unfortunately, the ATtiny2313A provides only 2 16-bit PWM channels (plus 2 8-bit channels), which is not really adequate. Using two ATtiny2313A chips would work, but for less money and less board real estate, we can use a PIC32MX110F016B-I/SP and get 16-bit PWM on a 40MHz clock for a 610.4Hz PWM frequency. The flexibility of the pin remapping on the PIC32 is attractive here, as it can simplify the routing of the board.

The processor not only has to interpret the DMX commands and provide PWM outputs, it also has to support the RDM (remote data management) protocol of modern DMX devices (the Tripar Profiles don’t, but there is no real excuse for not supporting RDM these days).

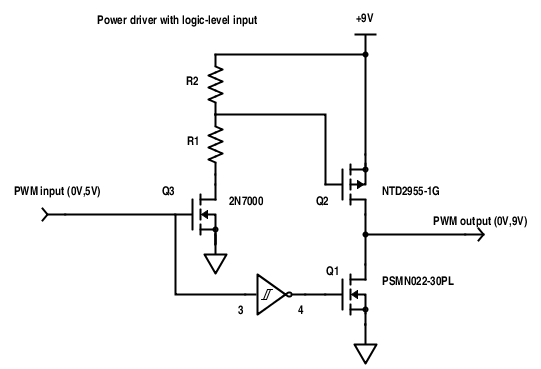

Here is a rough block diagram of the current design:

We’ve given some thought to the heat sink, fan, and mounting brackets for everything, but there is still more work to be done to make sure that we can really dump all the waste heat and keep the LEDs sufficiently cool. We’re currently looking at about $80 in parts for the light (not including the can, which we’ll get from WEST) plus another $15 to make a USB-DMX interface that can handle the RDM protocol. Those numbers may change a fair amount as we play with the design.

The two boards are each about 10cm by 5cm, which cost only $12 (for 10 copies) from Smartprototyping. My son has done preliminary layouts of them, to see how big the boards would be and determine any mechanical problems we might encounter.