Today I spent about 10 hours on the 2017 Santa Cruz Mini Maker Faire. The hours for the Faire were 10–5, but I spent some time setting up and tearing down afterwards, so I left the house around 8:30 a.m. and had the bike trailer unpacked and everything back in the house by about 6:30 p.m. I figure that I spent only about 10 hours earlier on setup for this Faire: applying for the Faire, setting out all the displays and testing them at home, preparing new blurbs for my book and blog, making table signs telling people how to use the interactive parts of the display, blogging about the Faire, and doing load-in last night. That is a lot less than last year, as I was able to reuse a lot of the design from last year.

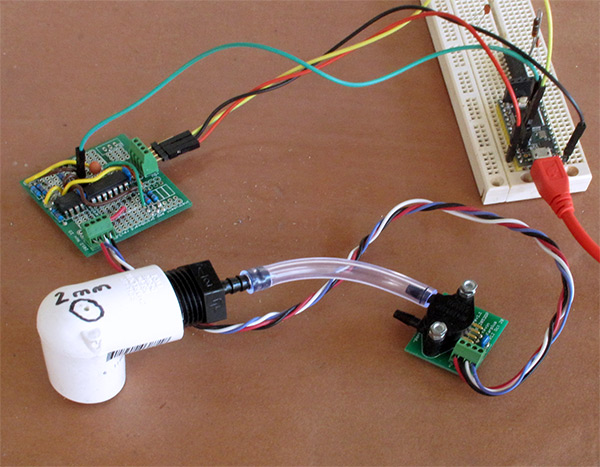

Here is the table display I ended up with:

The bare corner at the front left was reserved for the students in my freshman design course who were coming to display their muscle-controlled robot arm, but they decided to set up in back (you can see one of the lead students in the background).

I had four interactive displays (from left to right):

- A pair of function generators and an oscilloscope showing Lissajous figures. I changed this from last year, as I did not use the FG085 function generator this year, but one of the function generators from the Analog Discovery 2. I still used the Elenco FG500, despite the very low quality of its waveforms, because it has a knob that is easy for kids to turn, and is easy to reset if they mess it up (unlike the jamming buttons on the FG085). I did not use the second function generator on the Analog Discovery 2, as I did not want kids playing with just a software interface (and a rather complicated one at that). It might even be worthwhile for me to build a simple audio sine-wave oscillator with a single big knob over the summer, so that I can have something for kids to play with that is fairly robust and that can’t be easily set into a weird state. I could even do two, just for Lissajous figures, though having one fixed oscillator worked well this time. I had the Analog Discovery 2 oscilloscope showing on the laptop next to the old Kikusui CRT oscilloscope, showing both the waveforms and the XY plot, so that I could explain to adults what was happening with the Lissajous figures and about the differences between classic oscilloscopes and modern USB-based ones.

A lot of people asked me about the Analog Discovery 2, which I was very enthusiastic about—Digilent should be giving me a commission! (They aren’t, although I’m sure I’m responsible for at least half a dozen sales for them, and a lot more if we go ahead with our plan to use them in place of bench equipment in my class next year.) - In front of the laptop showing the Lissajous figures, I had a standalone optical pulse monitor using the log-transimpedance amplifier and the TFT LCD display. Using the log-transimpedance amplifier worked well, as did using a lego brick to block light to the sides and back of the phototransistor. A lot of people have trouble holding their hands still enough to get good readings (particularly children), so it would be good to have some sort of clip instead of resting a finger over the phototransistor. I’ve tried making clips in the past, but I’m not good at mechanical design, and I’ve always ended up with either a clamp that is too tight (cutting off circulation and getting no reading) or too loose (falling off). Ideally, I’d want a pressure between systolic and diastolic pressure, so about 12kPa (90mmHg). People did like the use of Lego as a support, though—it provided a familiar element in the strange world of electronics.

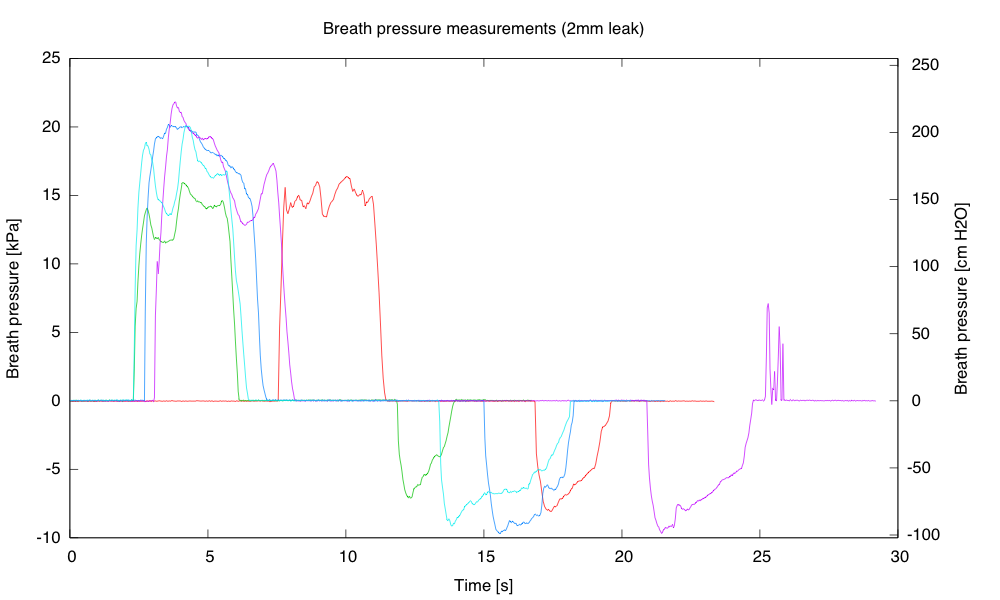

- To the right of the pulse monitor was a pressure sensor. I had a mechanical gauge and the electronic sensor both connected to a piece of soft silicone tubing taped to the table top. Kids pressed on the tubing to get an increase in pressure, visible on the gauge (about 20–60 mmHg) and on graph PteroDAQ was running on the little laptop (which we refer to as the “Barbie” laptop, because of its color and small size). I explained to kids that the tubing was like the tubing stretched across roads sometimes to count cars, with a pressure sensor that recorded each pulse as wheels compressed the tubing. (For some of the old-timers, I reminded them of when gas stations used to use a similar system.)

PteroDAQ worked well for this setup, running all day at 20 samples per second without a glitch. The only problem was occasional display sleep from the laptop, fixable by touching the touch pad. - At the far right end of the table, I had a phototransistor which kids could shadow with their hands, with the result visible on another channel on PteroDAQ. This was a last-minute change, as I was getting very unreliable results from the capacitive touch sensor when I tested it out last night. The capacitive touch sensor worked fine at my house, but in the kindergarten room at Gateway I has a different electrical environment, and it would not work unless I grounded myself. Rather than fuss with the touch sensor, I made a new table sign and put in a light sensor instead.

I might want to experiment this summer with different ways of making touch plates—trying to get one that doesn’t rely on the toucher being grounded. My initial thought is that if I have two conductors that are not too close together, but which would both be close to a finger if the touch plate is touched, then I may be able to get more reliable sensing. I could try some wire-and-tape prototypes and maybe make PC boards with different conductor layouts. (OSH Park‘s pricing scheme would be good for such tiny boards).

I also had my laptop displaying my book; some quarter-page blurbs with URLs for my book, PteroDAQ, and this blog; my 20-LED strobe; my desk lamp; and a PanaVise displaying one of the amplifier prototyping boards.

I’d like to think of a more exciting project for kids to play with next year—perhaps something I could build over the summer. Readers, any suggestions?

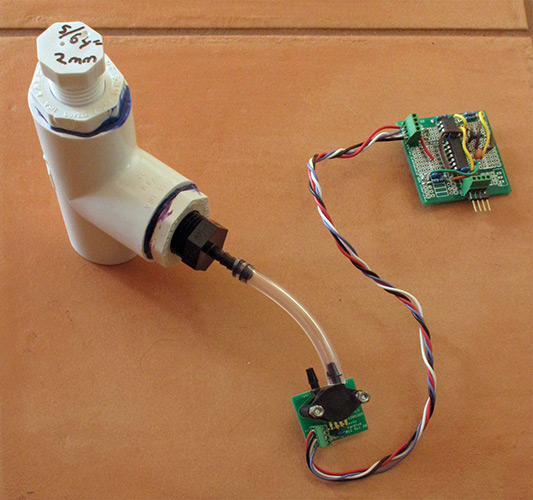

In addition to my display, some of the freshmen from my freshman design seminar class demonstrated their EMG-controlled robot arm (which uses the MeArm kit):

The students built a MeArm from a kit, then programmed a Teensy board to respond to muscle signals amplified by amplifiers designed by other students in the class. The combined project had two channels: one for controlling the forward-backward position of the arm (using the biceps), the other for controlling the gripper (using muscles in the forearm). With practice, people could pick up a light object with the robot arm.

The scheduling of the Mini Maker Faire was not ideal this year, as it conflicted with the Tech Challenge, Santa Cruz County Math contest, the California Invention Convention, and the Gem and Mineral Show, all of which draw from the same audience as the Mini Maker Faire.

The Faire seemed to be reasonably well attended (rather slow for the first hour and half, but picking up considerably in the afternoon). There was plenty of room for more exhibitors, so I think that organizers need to do a bit more outreach to encourage people to apply. It would probably help if they were quicker responding to applicants (it took them over three months to respond to my application, and then only after I nudged them).

Some obvious holes in the lineup: The Museum of Art and History did not have a display, but I saw Nina Simons there, and she said that MAH definitely plans to do it next year, but the Abbott Square renovation is taking up all their time this year. The fashionTEENS fashion show was April 21, just over a week ago, so it would have been good to get some of them to show their fashions again: either on mannequins or as a mini-show on the stage. It might be good to get some of Santa Cruz’s luthiers or fine woodworkers to show—we have a lot of top-notch ones, and many do show stuff at Open Studios. The only displays from UCSC were mine and the Formula Slug electric race car team.

Of the local fab labs, Cabrillo College Fab Lab and Idea Fab Labs were present, but The Fábrica and the Bike Church were not. I thought that Cabrillo did a great job of exhibiting, but Idea Fab Labs was a little too static—only the sand table was interactive.

It might be good to have Zun Zun present their Basura Batucada show (entirely on instruments made from recycled materials) and have a booth on making such instruments. It might be hard to get Zun Zun to volunteer, but they used to be very cheap to hire (I hired them to give a show at my son’s kindergarten class 15 years ago—they were very cheap then, but I don’t know what their prices are now).

One problem my wife noted was the lack of signs on the outside of classrooms, so that people would know what was inside. The tiny signs that the Faire provided (I think—I didn’t get one) were too small to be of any use. It may be enough to tell makers to bring a poster-sized sign to mount. I had my cloth banner behind my table, but a lot of the displays were hard to identify. Instructions or information mounted on tables would also have been good—again these would have to be provided by the makers. I did not see people carrying maps this year—they can also be helpful in getting people to find things that were tucked away in odd corners. Not many people made it back to the second kindergarten room where FabMo and the Lace Museum activities were.

Update 2017 May 1: It turns out that there were some things I missed at the Faire. The principal of Gateway sent me email:

… we did have 4 of the Fashion Teens exhibit their creations on the stage at 11:30—might be cool to have them put those on mannequins and have a booth next year. Also we had two more UCSC projects—Jim Whitehead and the Generative Art Studio, and Project AWEsome from the School of Engineering. We would LOVE to have more UCSC-related projects …